There will be a wide range of options to choose in tooling plates, including which supplier to buy from. Often known as cast jig & tool plate or CT&J plate, this is the ideal material for the construction of many parts and components, including tools and jigs.

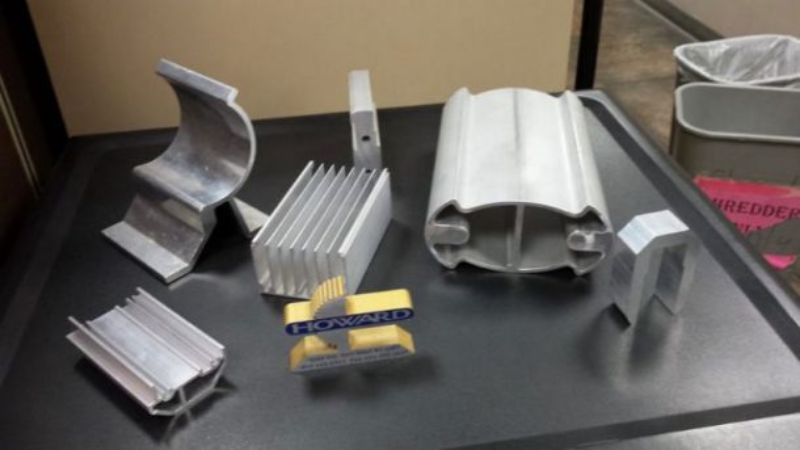

It is also used in the development of printing equipment, automotive parts, electronics, molds for rubber and plastic, medical instruments and devices and all types of CNC equipment and tables.

Benefits

Unlike other types of aluminum plate, tooling plates are not designed to have a lot of strength. This is very different than the plate used in the aerospace and defense industry. Instead, this plate is uniquely produced to have a very fine internal grain. This fine grain allows for the stability of the metal, which is very important in these applications.

The fine grain is stress relieved during the production of the plate. This means that when it is machined, the grains surrounding the area do not alter their configuration as will occur in other types of aluminum plate. The result is a part and plate that will not deform after machining, eliminating the need for additional processing.

Using the right equipment to machine tooling plates results in very high tolerances, up to thousandths of an inch without the need to rework any of the components. Additionally, this extremely flat plate is also lighter than many other alloys, making it easier to work with as a raw material or in tools and other parts.

Tolerances

Different options in cast, jig & tool plate do have different tolerances. This includes the thickness, width, and length, flatness and roughness. Additionally, when precision sawed and milled, surfaces and edges are always true and optimal condition without the need for milling or additional work.