Every large city and many smaller ones have machine shops which can handle most machining needs. However, when you want the ultimate in precision machined parts, the way to guarantee the company has the experience and qualifications is to find one which has the certification and experience to prove they are an aerospace machine shop.

While approval and awards are certainly something which the companies are working as aerospace machine shops often garner and of which they can be proud, the companies should also take the same amount of care and experience in fulfilling the orders of any customer, not just those in search of an aerospace machine shop.

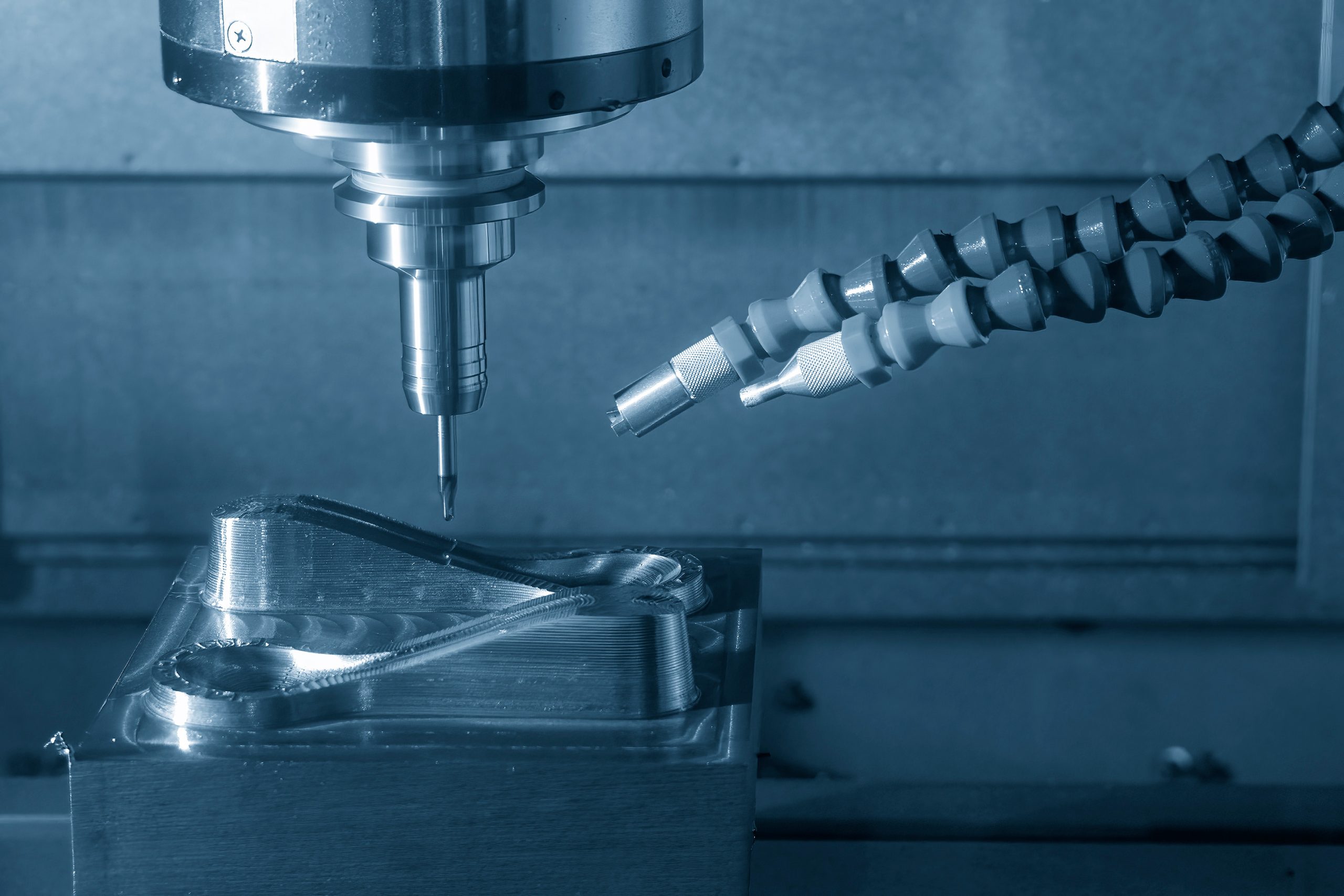

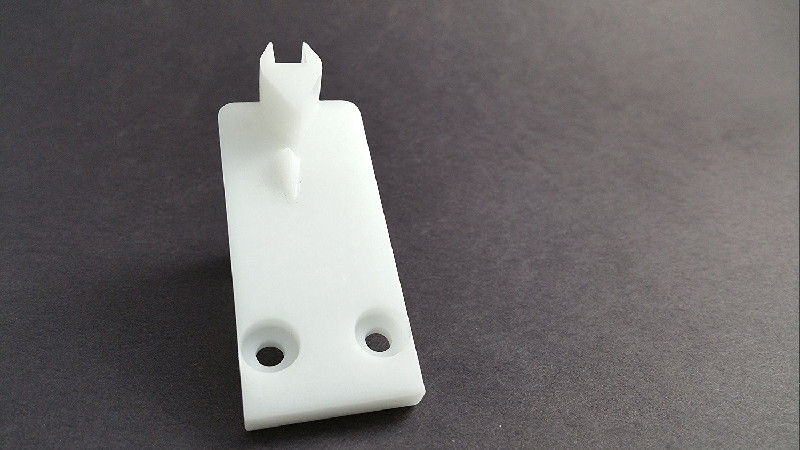

A competent machine shop should be able to provide a number of machining services to its current and prospective customers. These include highly accurate 3D milling, boring operations to the customer’s specifications regardless of the shape and/or size of the part, complete turning and threading operations using state of the art CNC machines and highly skilled operators. In addition, by using combinations of drills and machines, the facility should be able to drill almost any hole in any location and then ream, tap, bore or thread the holes as the customer requests.

Machine shops can vary in size, but a savvy customer knows that the size of an operation is no guarantee of its quality. Many machine shops start out small and at some point, have to make a decision on whether they can grow and still maintain a level of quality which customer will accept. Other machine shops, particularly if they are owned by or are a subsidiary of a larger company, may start out with many employees and many machines. While that facility may be more impressive at first glance, they can often lose their focus and not be as detail-oriented as a small company.