As an OEM, the design and development stage of any new part, component, system, or machine is always a critical time. This is the stage of brainstorming and research, and looking for ways to build a better product that offers durability, longer life cycles, and better efficiency than other similar products on the market.

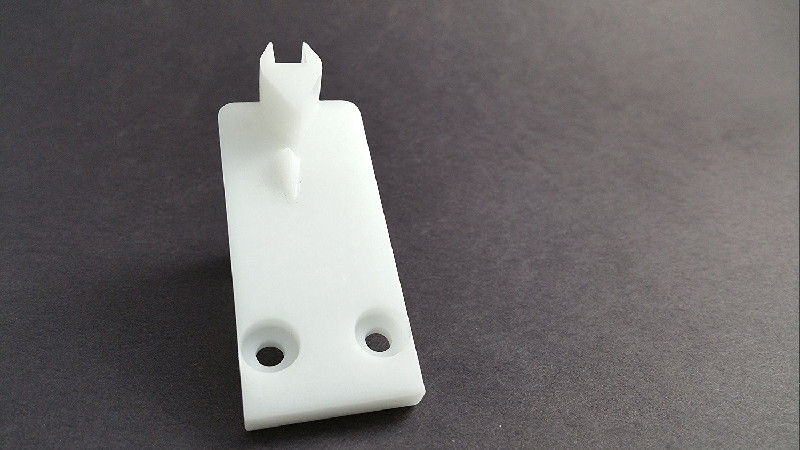

With this type of process in mind, the design that is developed is often unique and requires custom parts and components. These may be small or large parts, and they may be made of standard types of materials or exotic alloys or even some of the new lines of extremely durable plastics.

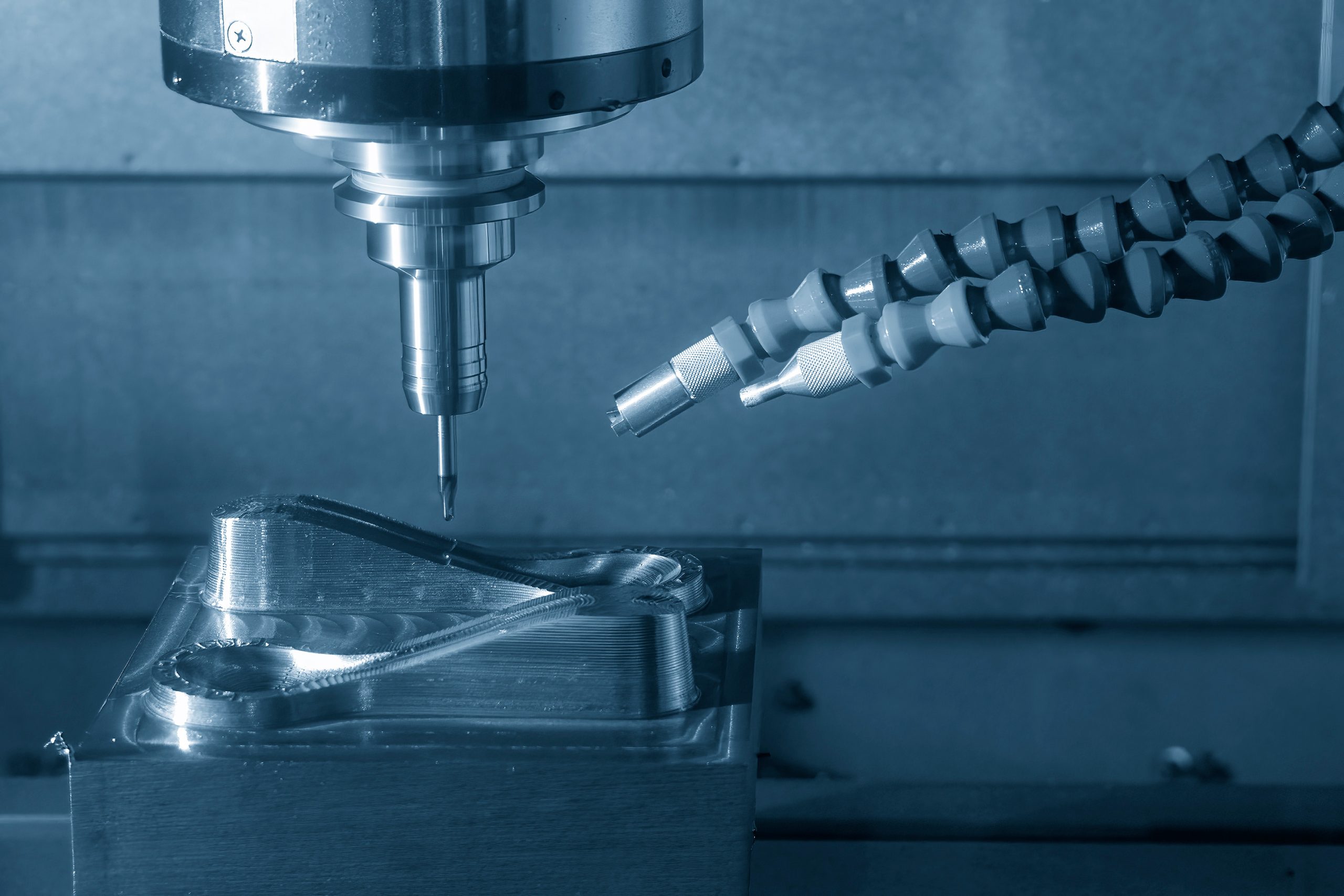

Creating these unique parts is part of the services offered by custom machining services. These companies can work with your design team to create a prototype of the component, and then move directly into production. They can also assist in keeping the cost of both prototyping and production low by making strategic recommendations.

Considerations of Material Options

Not all metals, alloys, and plastics are easily machined. When working with experienced custom machining services, discussions around the cost of using specific types of materials can assist the OEM in developing a prototype to production model that uses materials that are lower in cost to machine without sacrificing quality, durability or performance.

services-offered-by-custom-machining-services

With any type of shapes and configurations required, there may be more than one piece of equipment required to complete the necessary custom machining services. The more times the workpiece or part has to be handled and moved between equipment, the more costly the process.

In some cases, the machining service may offer a multi-axis machining center, which is very effective at complex shapes. However, this is not always possible given the size of the part, and knowing your options in advance can help in considering the cost of production.