The process of extrusion when it comes to shaping materials like aluminum is done by forcing it to flow through a shaped opening in a die for it to emerge as an elongated piece with the same profile and characteristics as the die opening. The sophisticated and detailed technologies involved in extruding a material garner the need for qualified and experienced professionals to handle it in order for the varied specifications of the clients to be met.

There are aluminum extrusion companies that are more than willing and ready to handle this detailed process to ultimately and legitimately provide the necessary tools for any given trade or product.

What Aluminum Extrusion Companies Offer?

The process of aluminum extrusion should be handled by experts who are willing to put a hundred percent or more guarantee on satisfaction. Companies that facilitate the detailed process of direct extrusion, which is when the die head is stationary and a moving ram forces the metal through it, and indirect extrusion, which is when the billet remains stationary while the die assembly at the end of the ram moves against the billet creating pressure needed for the metal to flow through the die.

It is imperative that facilitation of the aluminum extrusion process be precise and forthright as many outsourced products are dependent upon this process being done. Thus, finding the best company means securing the best results in the copious process of aluminum extrusion for the particular application.

Aluminum Extrusion Companies as a Resource

These companies are a needed resource in the handling of extrusion for a variety of applications that help the function and structure of products that may include rescue vehicles, schools, docks, commercial and residential architecture, and manufacturing and installation companies, and more.

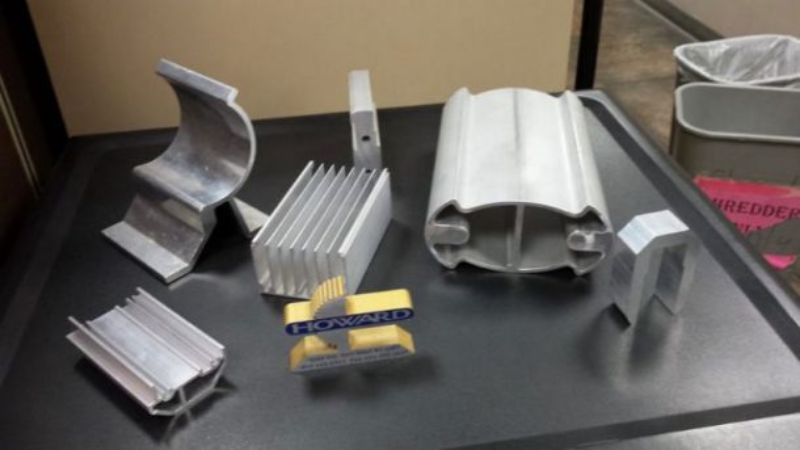

Aluminum in its most varied usage can be difficult to come about depending on its specific need, but quality and experienced companies can offer a range of possibilities, some reaching into ten thousand dies and shapes. Using these companies as a resource to supply a specific need is advantageous not only in the detailed process of extrusion but in making sure it is done correctly and most efficiently.