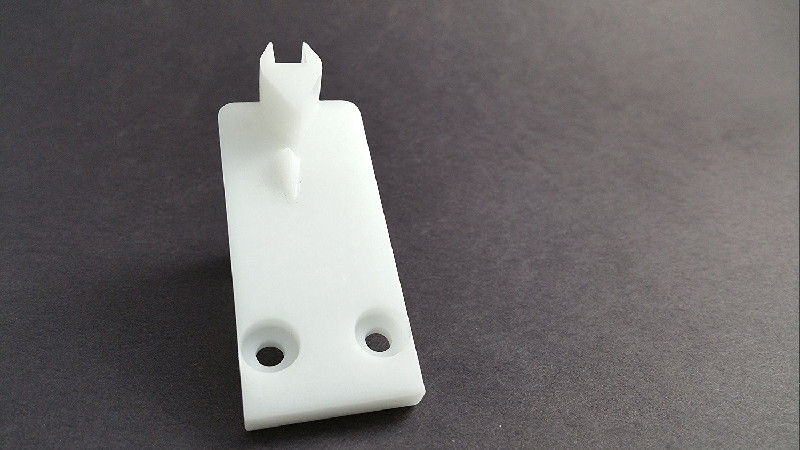

When you think of a modern machine shop, you might think of precision engineering and machining services for steel, aluminum, and other metals. However, modern plastics have come a long way in a short time, and they can be machined and shaped with precision. Here are some benefits of CNC plastic machining you may not be aware of.

What about Injection Molding?

Many parts today are made with injection molding methods. However, injection molding has its limitations and cannot create precision parts with high tolerances. Many of today’s plastics are tough and durable enough to machine with great precision if you have the right equipment, knowledge, and experience.

Plastics Vs. Metal

Machining plastics with precision can help you create parts or components which are lighter than many metals today, even aluminum alloys. In the past, many parts were made from aluminum because it is lighter than steel and resists corrosion. However, some alloys of aluminum are expensive, and you can get many of the same benefits of aluminum with today’s plastic materials and CNC plastic machining technology.

Stay Ahead of Competitors

Using plastics can give you an edge on the competition for several reasons. First, you can create lighter parts, and in the automotive industries, weight is an important issue, as automakers must meet stiff standards set on fuel mileage, and these standards continue to get tougher.

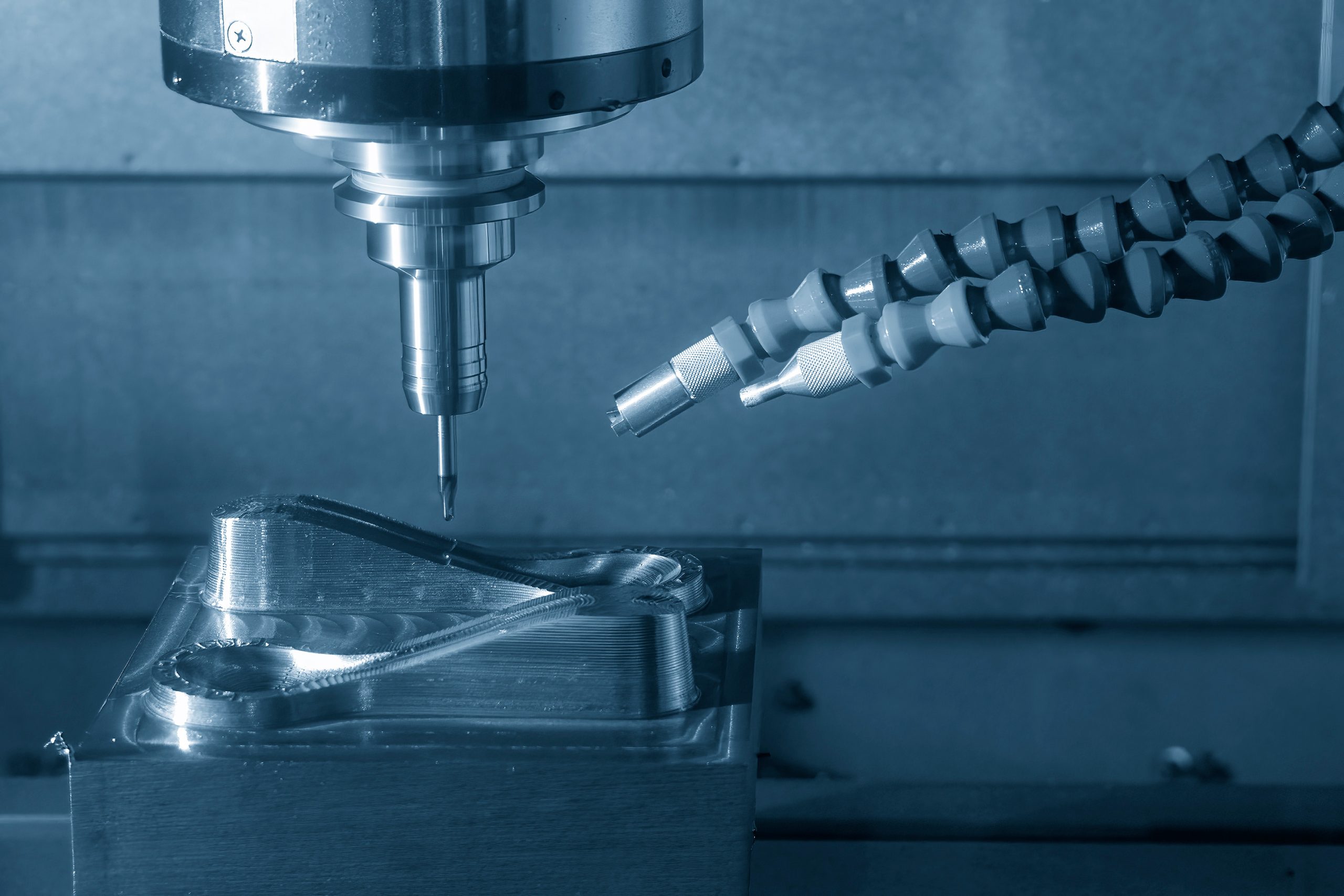

Computer Numeric Control

Using plastics gives you advantages in business, but you can increase those advantages when you add CNC technology. CNC plastic machining uses computer programs to guide precision machinery through the process of milling, turning, threading, and boring.

Winning the Numbers Game

CNC technology can create parts faster and with greater precision than most manual machining methods. This produces lower cost parts and faster turnaround times. Talk to your CNC shop today about the many things they can do for you.