Rigging consists of operations that lift and relocate various types of large objects and structures in a secure manner. The rigging equipment and supplies that are used to carry out these tasks include wire rope, master links, sling shackles, and lifting magnets. There are multiple industries that benefit from the application of heavy rigging assets and services, such as oil and gas, pipelining, manufacturing, and mining.

Large Equipment Benefitting from Rigging Hardware

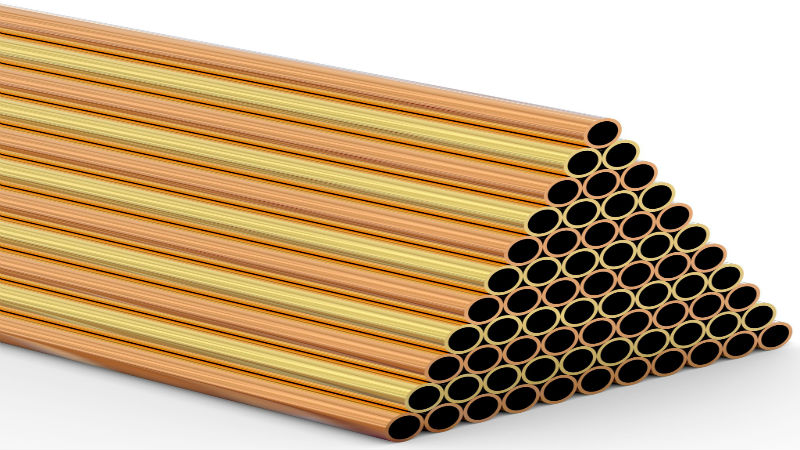

Rigging equipment is put into service on a continual basis across the nation for the purpose of relocating heavy loads, plates, beams, pipes, and other objects. This type of equipment often includes the use of Crosby hardware products and supplies. Some of the types of equipment commonly used in rigging applications include mobile crane trucks, winches, overhead shop cranes, recovery vehicles, and personal jib cranes.

Crosby Rigging Devices and Hardware

Rigging hardware, supplies, and equipment are often built using some of the highest quality materials available, including carbon steel, high tensile steel, and alloys in order to meet the specific requirements of rigging applications. The premier and most important aspect of these operations is their safety from start to finish. The range of devices and hardware used in conjunction with other types of rigging equipment include blocks and sheaves, swivel hoists, wire rope end fittings, Crosby IP clamps, Marine and western blocks, eye bolts, grip clips, wire rope clips, chains and accessories, hooks, swivels, and shackles.

Other Rigging Supplies

Along with the equipment and supplies mentioned above, other resources may be of considerable benefit to rigging professionals and utilized in conjunction with rigging operations in numerous industrial projects. These resources can help rigging professionals perform projects safer and more efficient manner.

Several of these resources include product information manuals and brochures, specialty products that assist in conforming to specifications and user requirements, repair services for rigging equipment and hardware, and inspection of rigging supplies and equipment onsite. The latter can help ensure proper and safe equipment operation and utilization through specific and rigid testing criteria and procedures.

Contact an experienced supplier of rigging products today to obtain the rigging devices you need for your application.