Conveyor systems are common in industries throughout the country and the world. One of the materials that facilitate steady and reliable system flow is plastic, specifically, high-performance plastic parts.

Types of Plastic Used In Conveyors

Several plastics appear in use in conveyor systems for various reasons.

Acetal

Acetal is commonly used to make plastic conveyor components in Washington and turns up frequently in food processing. Acetal is a high-performance material that facilitates quiet and smooth conveyor systems due to its low coefficient of friction.

UHMW

A frequently used material for plastic conveyor components in Washington is UHMW, or ultra-high molecular weight polyethylene. UHMW has unique characteristics suitable to the job, including low moisture absorption, low friction attributes and a resistance to bridging or arching.

Some kinds of UHMW and Acetal are also detectable with X-ray and metal detectors and are useful in operations where contamination is a concern.

Industries That Use Plastic Conveyor Parts

Many industries utilize plastic conveyor parts, these include:

- Product Processing

- Wood Processing

- Water Treatment Facilities

- Beverage and Bottling

- Bakeries and Car Washes

- OEMs

- Sand and Gravel

- Agriculture

- Material Handling

- General Industrial

- Food Processing

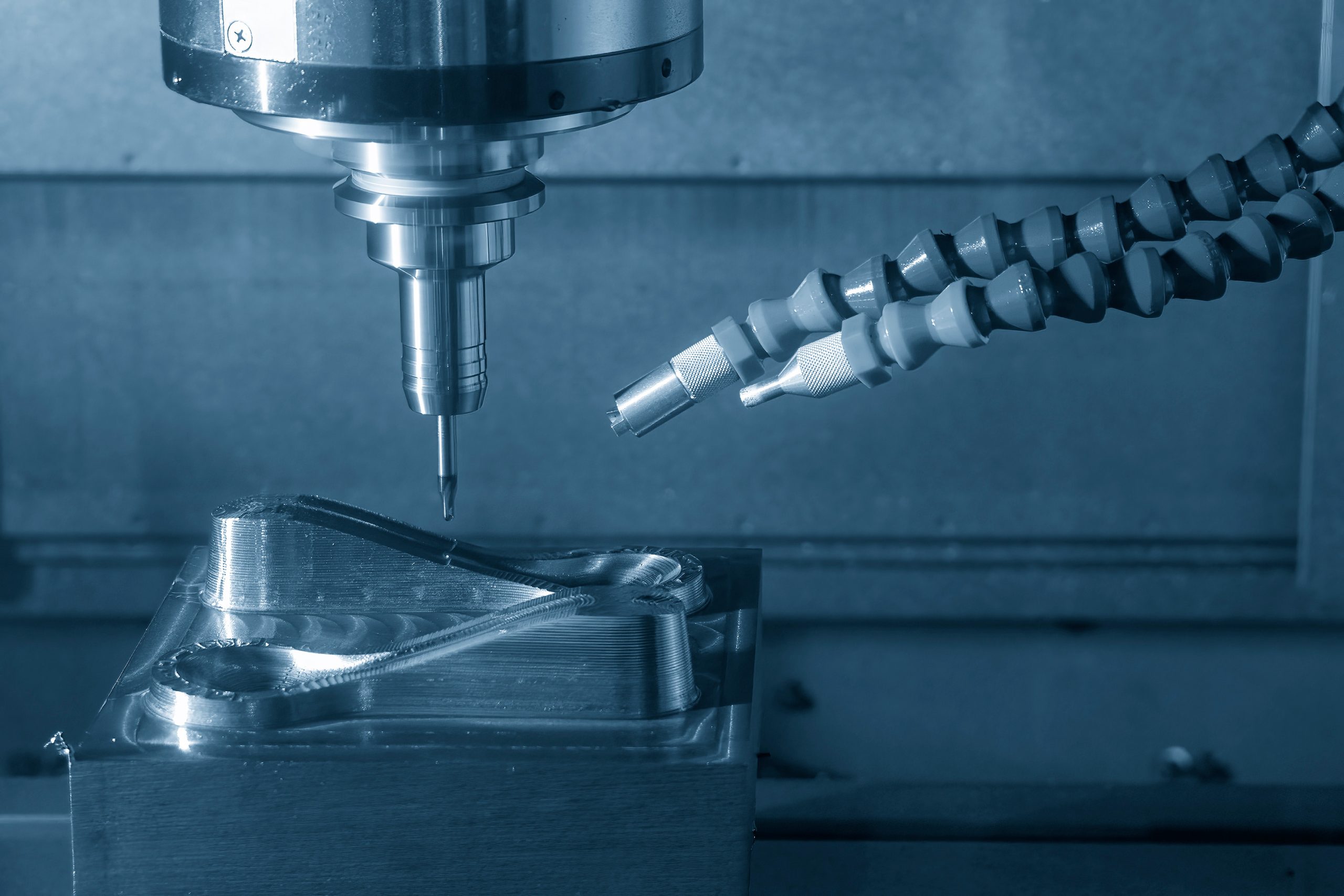

Custom Plastic Components

Plactic CNC machining lets companies manufacture custom components that meet the unique demands of a specific design or application. Whether it’s bearings, bushings, sheaves, pulleys, pillow blocks, wheels or shaft collars, plastic CNC machining can realize the part to tolerances as low as 0,002″ and in multiple plastic types.