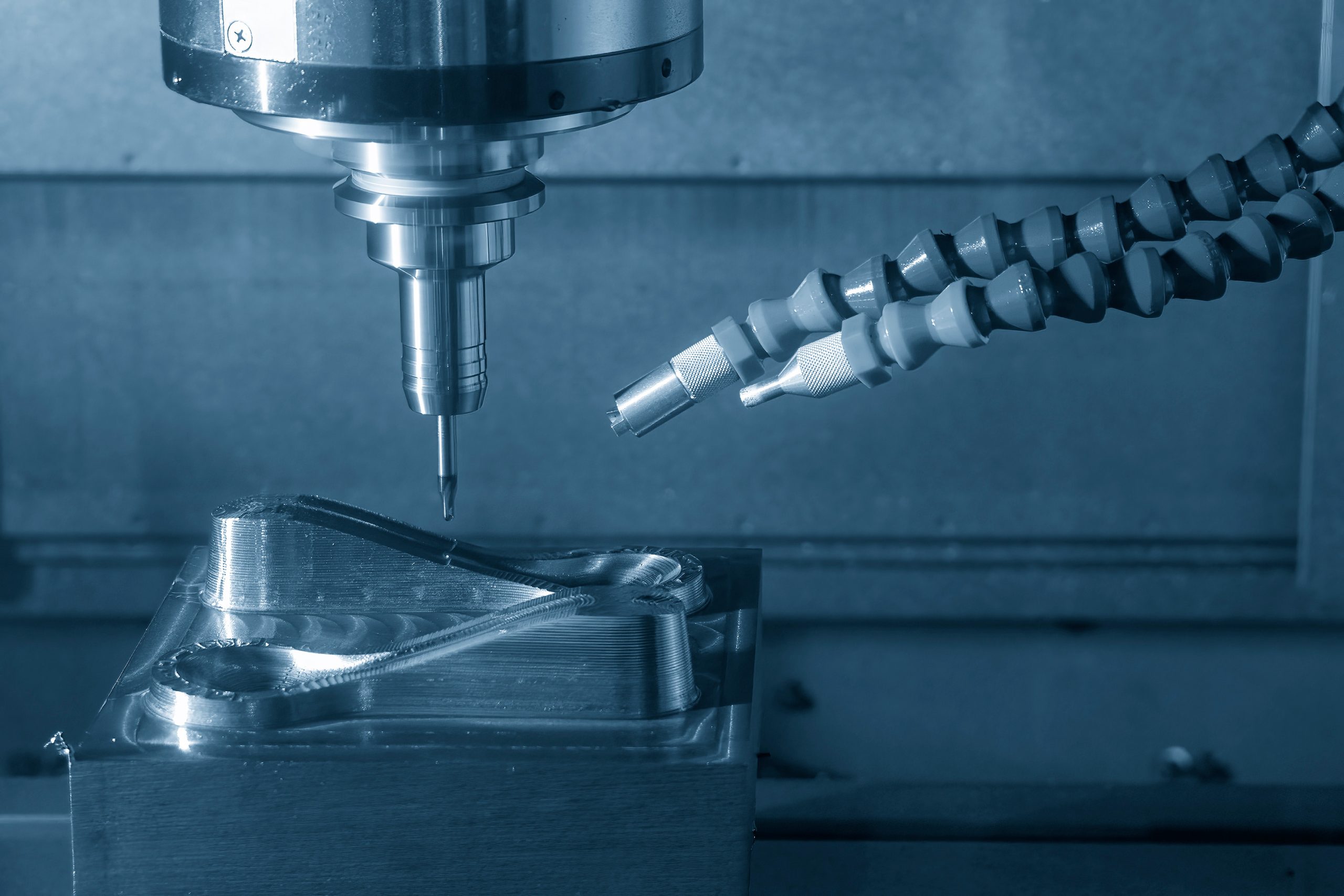

If your business does its own machining, you may have the need for many different parts and materials. Most of the time, your shop can handle the production of a wide range of parts. But what happens when you want to design and produce something new? New products are a great way to expand your business and customer base, but it can take a lot of resources for research and development. If this is the case, you might want to consider prototype machining and the many benefits it will provide.

What is a Prototype?

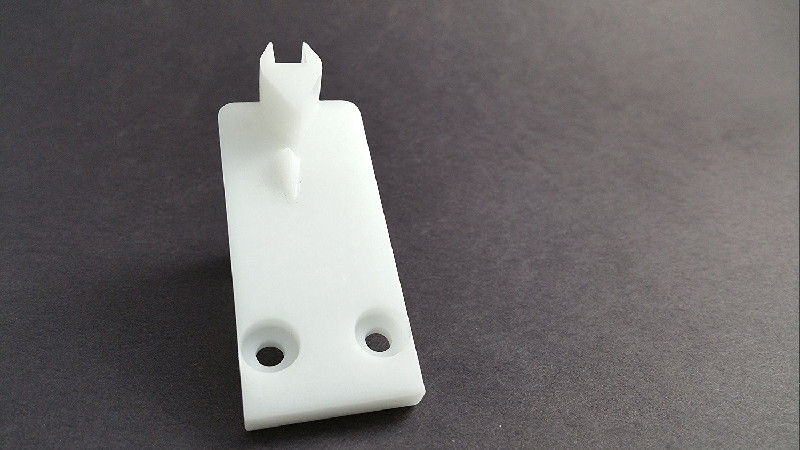

Prototypes are also known as “working models”. For example, suppose you have an idea for a new grease gun applicator. Your design will include a built-in valve to keep grease from leaking out after application. You may not be sure if your idea is going to work or not.

You develop plans for your new applicator with a series of drawing and a detailed explanation of what the part does and the problems it is designed to solve. Instead of going straight to production, you create a working model with the help of prototype machining. This model can be studied and tested to see if your idea is valid and the new applicator will meet the demands placed upon it by the customer. This is the basic idea behind prototypes.

Why Make Prototypes?

Improved quality – you can test your working model as much as you wish and testing may show up design or manufacturing flaws. It gives you the chance to bring a new product to production which has been extensively tested and examined.

Spot problems early – with a working model of you new idea, you can find flaws early in the process. In other words, prototypes can be produced quickly and they do not have to be perfect. In fact, you may need to create several versions until you get it right.

Fewer recalled products – most products today are recalled because of design issues. However, the more you create prototypes and test them, the fewer recalls you’ll have to worry about.

Fewer legal problems – no manufacturer or machine shop wants to deal with product liability lawsuits. They can be very expensive and even if you win, you could be out a great deal of legal expenses.

Cost savings – discovering problems early and correcting them is much cheaper than making changes later. In addition, there are fewer production headaches to be concerned with when you take advantage of prototype machining.