The need for Metal Strapping Tools is somewhat specialised but is probably larger than many of us might think. The name is fairly self descriptive but bear in mind that these are tools that assist you when you are working with metal straps.

What Do You Do With Straps In General?

Straps are relatively narrow strips of material that is thin enough to go tightly around sharp corners and they are used for such duties as tying bundled items together, holding things in place or securing the openings in things like carton boxes and wooden crates. For such work, straps are often referred to as bands to differentiate them from straps that keep clothing in place on the wearer’s body or, something like a helmet strap etc. Banding straps generally have a more industrial and/or heavier duty field of application.

Being for heavier duty use, these industrial grade straps are made from either high strength plastic strip or strips in various metals – mainly carbon steel for general purpose or stainless steel should higher strength and greater resistance to chemicals, corrosion and higher temperatures be required. The strip for these straps is manufactured in very long length strips that can be cut to suit the periphery over whatever it may be that they have to pass around. But simply passing them around something will not serve any purpose. The strap has to be pulled tight and then its two ends must be joined together. Unlike the string around a parcel, you are not going to be able to tie the ends of these straps together.

Pull Tight Then Seal Or Join The Strap Ends

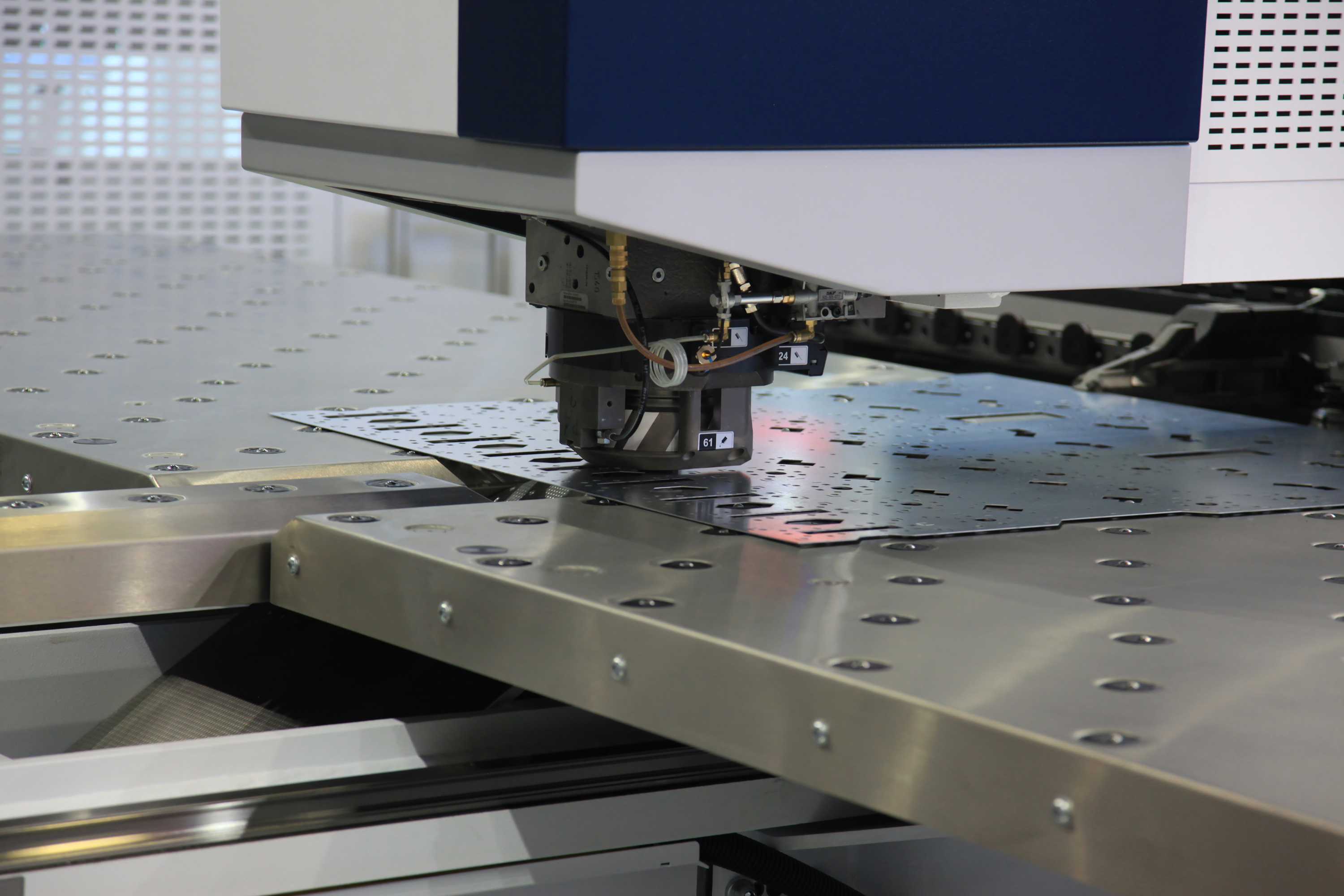

For metallic strapping; this is the job performed by Metal Strapping Tools. Generally speaking, the terminology only applies to hand held tools. For something like a packaging production line where the product is boxed and then the boxes are closed with metal straps, an automatic metal strapping machine would replace the hand held Metal Strapping Tools.

The metal strapping will probably be on a reel in a dispenser and the tools will extract and cut sufficient for the job in hand and then fix one end and pull the other tight around the item being strapped. Since it would be hardly practical on most cases to tack weld the two ends together, some sort of mechanical crimping will be required once the strap is under tension. Often, this involves inserting both ends into a thin metal sleeve known as a seal and crimping the three pieces together in a slip-proof manner. These separate stages might be carried out by separate or combination Metal Strapping Tools.

Independent Metal Strap Co., Inc not only supply all grades of metal strap; they also produce a full line of USA made Metal Strapping Tools.