In today’s competitive manufacturing landscape, efficiency is the cornerstone of success for any CNC precision machine shop. As technology evolves, so do the methodologies to enhance productivity without compromising on quality. This article delves into the best practices that can significantly boost the efficiency of your CNC operations.

Streamlining Workflow

Optimal Machine Layout

The arrangement of CNC machines within the shop plays a crucial role in operational efficiency. Ensure machines are laid out to minimize movement between operations and facilitate easy access for maintenance. This reduces downtime and enhances workflow continuity.

Automation and Robotics

Incorporating automation through robotics can drastically reduce manual tasks such as loading and unloading components. Automated tool changers and pallet changers are examples that speed up the machining process while maintaining precision.

Enhancing Machine Performance

Regular Maintenance

Preventative maintenance is key to avoiding unexpected machine downtime. Implement a regular maintenance schedule that includes checking and replacing worn components, lubricating moving parts, and updating software.

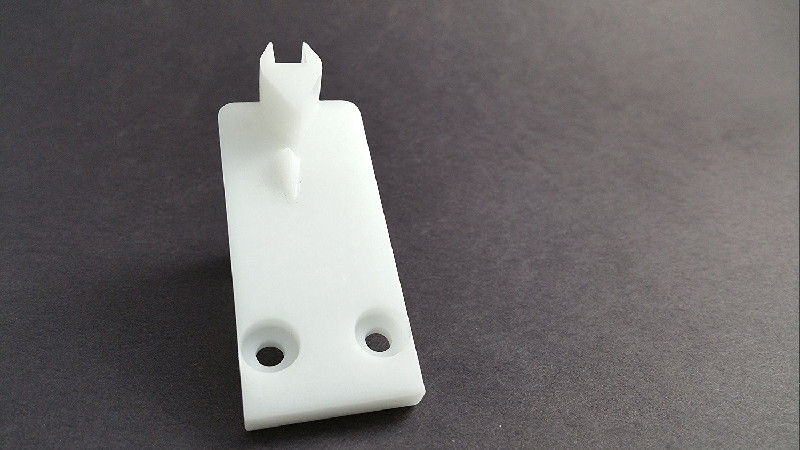

Tool Management

Efficient tool management ensures that the right tools are available and in good condition when needed. Using a tool management system can help track tool life and usage, preventing delays caused by worn-out tools or tool shortages.

Leveraging Technology

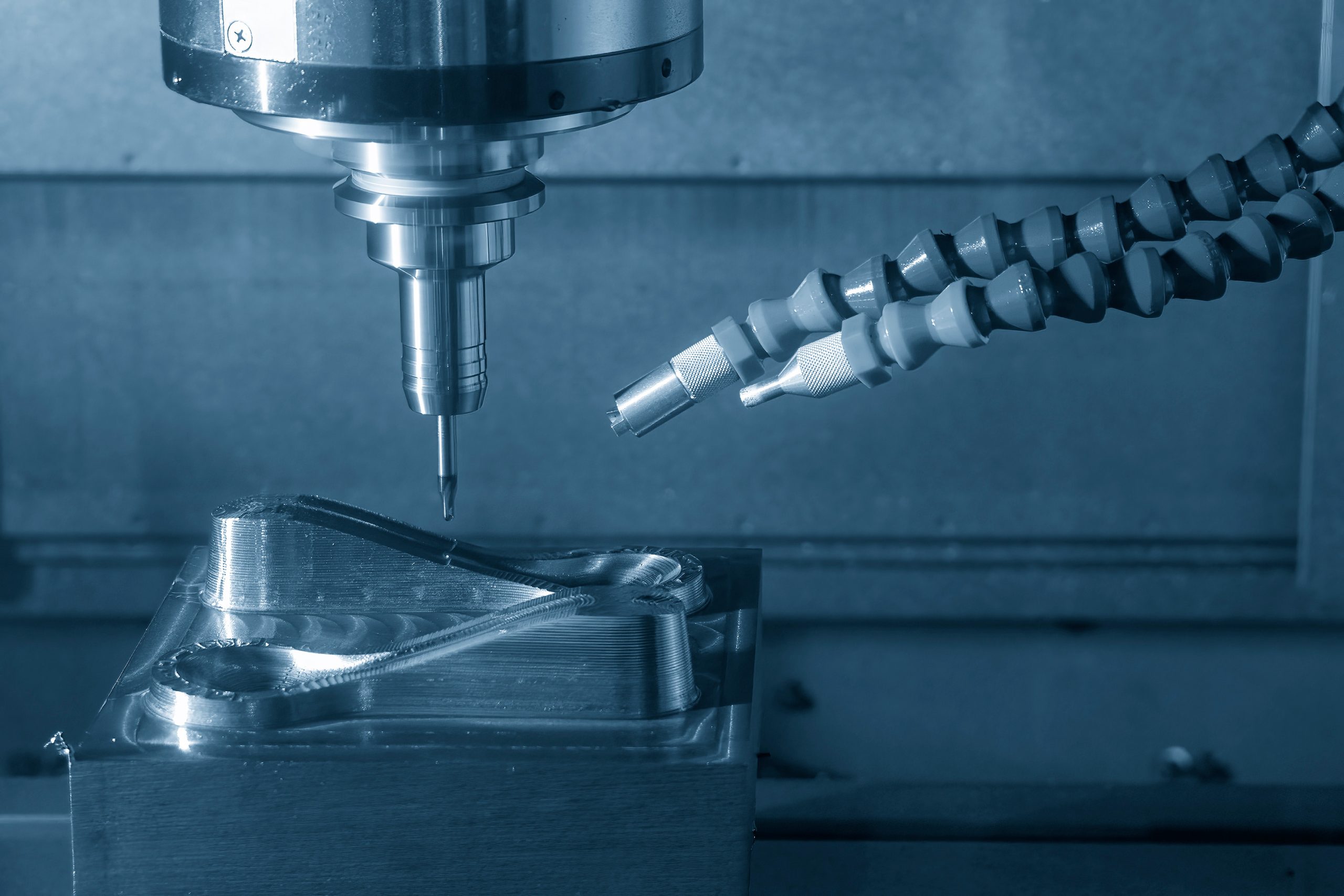

Advanced Software Solutions

Utilize the latest CAD/CAM software to enhance the capabilities of your CNC precision machine shop . These tools offer optimized cutting paths and efficient programming options that reduce waste and increase throughput.

Data Analytics

Implementing data analytics can lead to significant improvements in machine shop efficiency. Analyze data to identify patterns and bottlenecks in the production process. This information can be used to make informed decisions about workflow adjustments, machine settings, and maintenance schedules.

Training and Skills Development

Continuous Training

The technology used in CNC machining is continually advancing. Regular training sessions for your team can help them stay updated with the latest techniques and software, thereby improving productivity and reducing errors.

Cross-Training

Cross-training employees can help in creating a flexible workforce capable of handling multiple tasks. This reduces dependency on specific individuals and ensures that the production line continues smoothly even in the absence of key personnel.

Conclusion

Maximizing efficiency in a CNC precision machine shop involves a combination of strategic planning, advanced technology, and continuous improvement in workforce skills. By optimizing machine layout, embracing automation, maintaining equipment, and leveraging cutting-edge software, shops can enhance their operational efficiency. Regular training and effective tool management further support these efforts by ensuring that both machines and personnel are prepared to meet the demands of modern manufacturing. Implementing these best practices will not only streamline your operations but also position your shop as a leader in the competitive CNC machining market.