Do you produce products which require lathe or turning operations? If so, you may need to upgrade to keep up with the competition. However, upgrading may not fit into your operating budget so what else can you do? You could keep on making the same things each year and hope your competitors do not pass you by. You also can outsource some or all of your turning services. Here are some important benefits of outsourcing your needs.

What is Outsourcing?

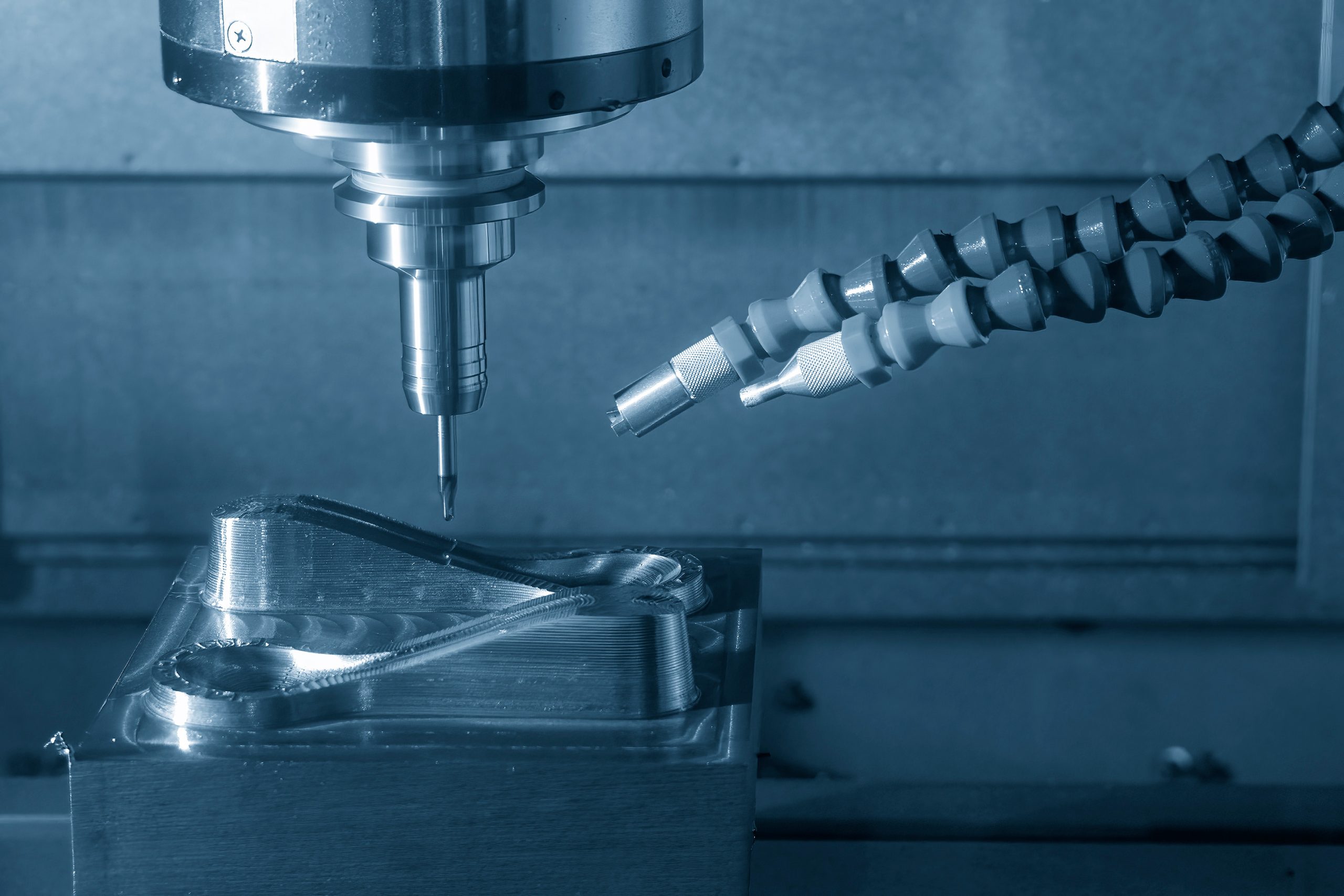

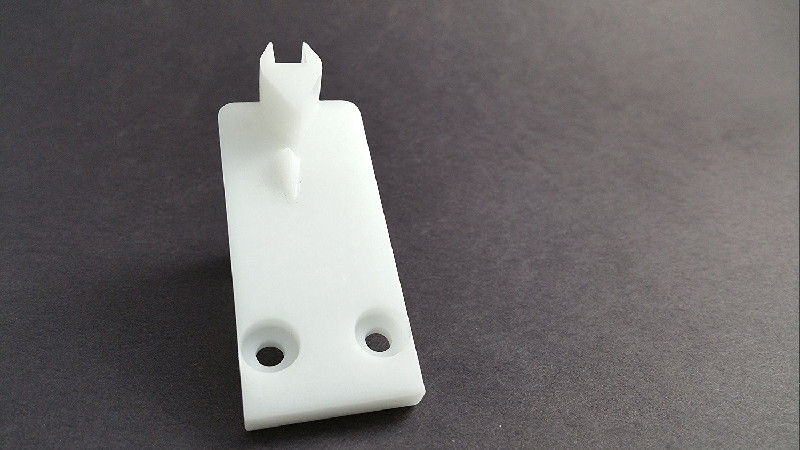

Outsourcing means you hire someone to take care of part or all of your manufacturing needs. Suppose you need 1000 parts turned by on short notice. However, you may have other customers to take care of, or you simply cannot handle this kind of volume for rush orders. Instead or disappointing one of your customers, you can go to a reputable shop offering turning operations. They can manufacture exactly what you need, and you do not have to lose any business.

Benefits

One of the biggest expenses many shops have today is labor. You can cut labor costs by adding CNC machinery, but this is an expensive option. Yet, if you outsource work, you do not use your staff, so you have no additional labor costs to worry about. There is no need to provide overtime pay because your workers have put in more than 40 hours per week.

Human Resources

Keeping up with your workforce is a full-time job. You need someone to oversee your operations, and some people may need training from time to time. When you outsource your turning operations, your management staff less to do.

Efficiency

Imagine increasing your production, gaining new business, and making more income with fewer people on your payroll. With outsourcing, you can increase efficiency, raise profits, and lower your operating costs. This is a good way to improve your overall efficiency.