The plate-style heat exchanger stands out in thermal management and heat exchange due to its efficiency and versatility. This compact and powerful device is valuable for a wide range of industrial and commercial applications. Its design and functionality make it an essential component for optimizing energy consumption and improving system performance.

The Design and Operation of Plate Type Heat Exchangers

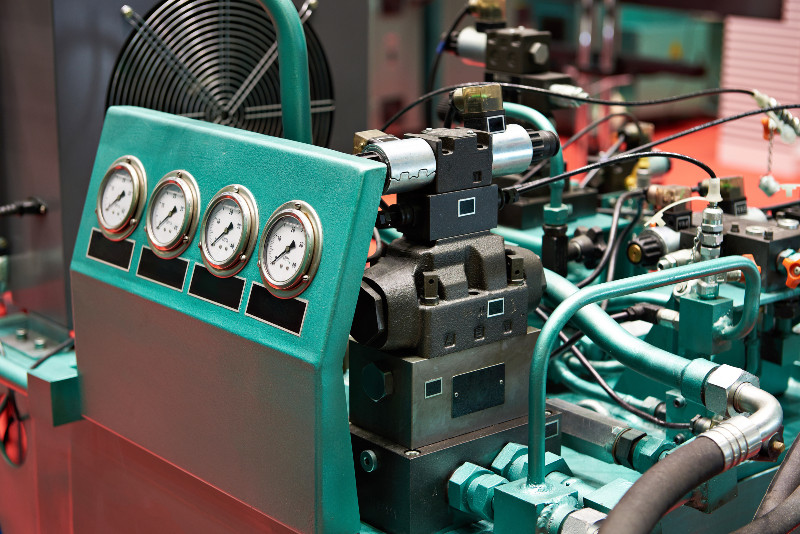

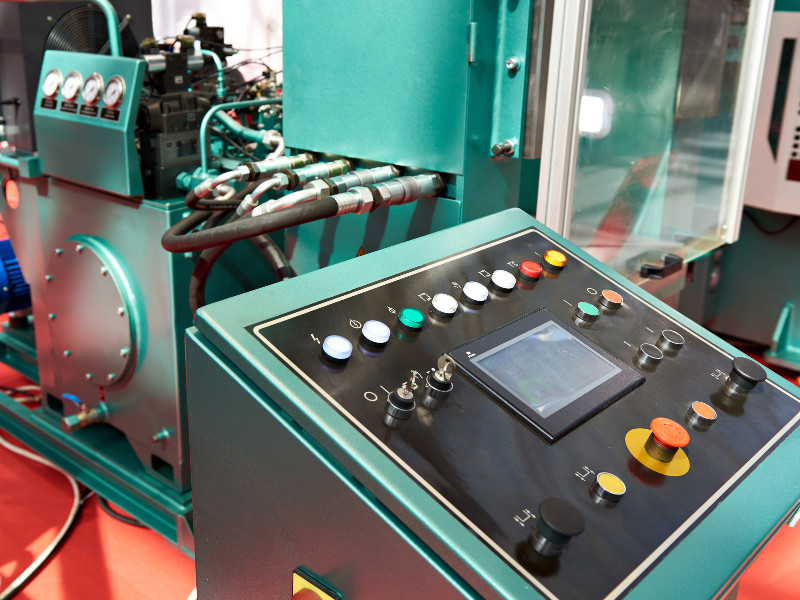

The plate type heat exchanger is made up of a series of thin, slightly spaced plates with large surface surfaces and fluid flow tubes for heat exchange. The design is simple but incredibly effective. A frame holds the plates in place, creating various channels for the flow of hot and cold fluids. This configuration enables effective thermal exchange between the fluids. One of the primary benefits of this heat exchanger is its ability to operate at a wide variety of temperatures and pressures while retaining excellent thermal efficiency. The proximity of the plates increases the heat transfer rate, making it an excellent choice for applications requiring effective heat exchange in limited spaces. This form of heat exchanger is especially useful in industries with limited space, such as chemical processing, HVAC systems, and food and beverage production. Its tiny design allows it to be seamlessly integrated into various surroundings while maintaining performance and efficiency.

Applications and Benefits

Heat exchangers are widely used throughout sectors due to their versatility and performance. In the HVAC industry, these devices play a valuable role in heat recovery and transfer inside heating and cooling systems, resulting in significant energy savings and lower operational costs. In the chemical industry, the ability to control high-temperature and high-pressure fluids is critical for process stability and safety. In the food and beverage industry, these exchangers are used to pasteurize and process liquids while adhering to strict hygiene standards. Their tiny design enables easy incorporation into existing systems with little modifications. Aside from their space and efficiency advantages, these heat exchangers are intended for simple maintenance and cleaning, which is critical in industries where cleanliness and process integrity are vital. Additionally, their modular design allows for easy extension or adaptation to meet changing needs.

Compared with Other Heat Exchanger Types

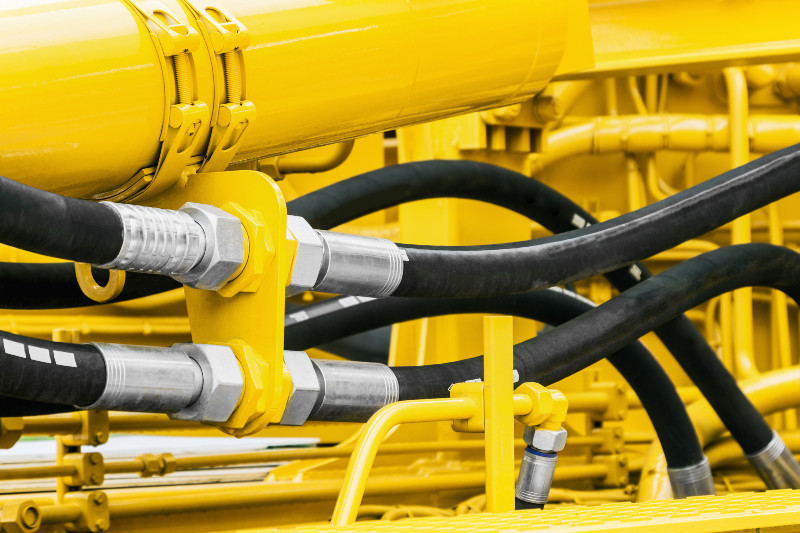

These heat exchangers have several significant advantages over other designs, such as shell-and-tube or air-cooled exchangers. Plate type heat exchangers have a heat transfer coefficient due to their large surface area and the turbulent flow caused by the plate channels. It results in higher performance in a smaller footprint. The ability to disassemble and clean individual plates simplifies maintenance compared to other varieties, which may necessitate more thorough disassembly. The benefits of increased efficiency and lower running costs frequently outweigh the initial investment in a plate-type heat exchanger, making it a cost-effective long-term option. The heat exchanger is an invaluable tool in modern thermal management. Its efficiency, compact design, and versatility make it appropriate for a wide range of applications across multiple sectors. Businesses that understand the benefits and applications of this technology can make better judgments regarding their heat transfer needs and optimize their processes for higher efficiency and cost-effectiveness.