In the world of modern manufacturing and engineering, the phrase “custom machining services” catapults intricate images of precision, innovation, and boundless potential. It’s the clandestine yet pivotal artistry that turns the drafts and blueprints of your most innovative designs into tangible, functional parts. From tweaks to tolerances to grand-scale unique prototypes, the array of needs and niches catered to by custom machining services knows no bounds.

Diverse Avenues of Machining Expertise

Custom machining isn’t a one-size-fits-all model. It encompasses a rich spectrum of capabilities, each suited to specific needs:

Computer Numerical Control (CNC) Machining: Is ideal for intricate, highly detailed, and repeatable projects.

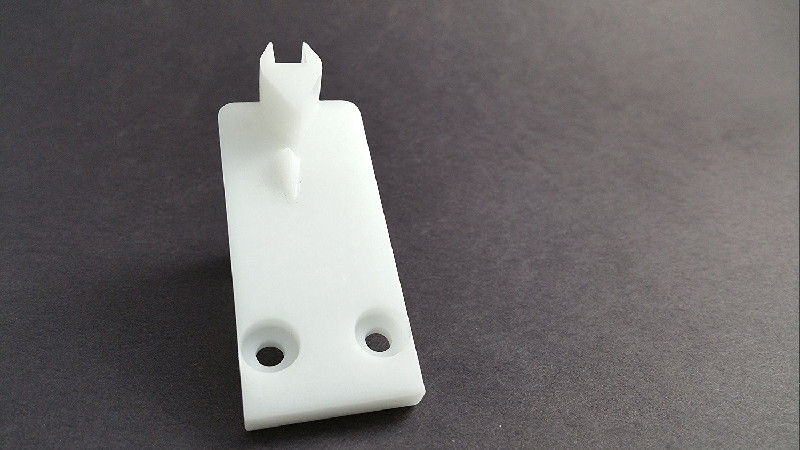

3D Machining: Utilizes 3D modeling to create detailed, complex prototypes and parts.

Multi-Axis Machining: Is where the movement of the cutting tools is controlled across more than three axes, allowing for more complex shapes to be machined.

Precision Machining: Caters to the need for tight tolerances and uncompromising quality.

The Allure of Customized Manufacturing

Embracing custom machining can lead to transformative results for manufacturers and engineers alike:

Tailored to Perfection: Precision in parts manufacturing is about more than hitting tolerances; it’s about crafting components that work seamlessly with one another.

Innovation Unleashed: Custom machining allows for the creation of uniquely designed parts that might not be possible with standard tooling or practices.

Speed and Flexibility: With the latest technology and expert operators, custom machining services can often provide a faster turnaround than in-house alternatives.

The Telltale Signs: When Custom Machining Is the Way to Go

Not every project requires the finesse and specialization offered by a custom machine shop. However, several scenarios call for their unique intervention.

Designs That Defy Convention

When your designs are unconventional, intricate, or unlike anything that off-the-shelf can match, custom machining steps in to bridge the gap.

The Tolerance Tightrope

Some industries demand precision at a microscopic level. Custom machining thrives on such tight tolerances, ensuring that each product meets the exact blueprint without exception.

Prototyping Prowess

In the prototyping stages, flexibility and speed are paramount. Custom machining can rapidly produce prototypes for testing and iteration, dictating the feasibility and functionality of the final product.

Balancing Budgets and Bespoke Production

Contrary to popular belief, custom machining can be a cost-effective option, especially when compared to setting up and maintaining in-house machining capabilities for unique components.