Coolant must always be filtered if it is to retain its consistency and effectiveness, but do you know why? Your coolant filter ensures that your machinery and the cutting tools remain operative long-term.

Consider Your Machines

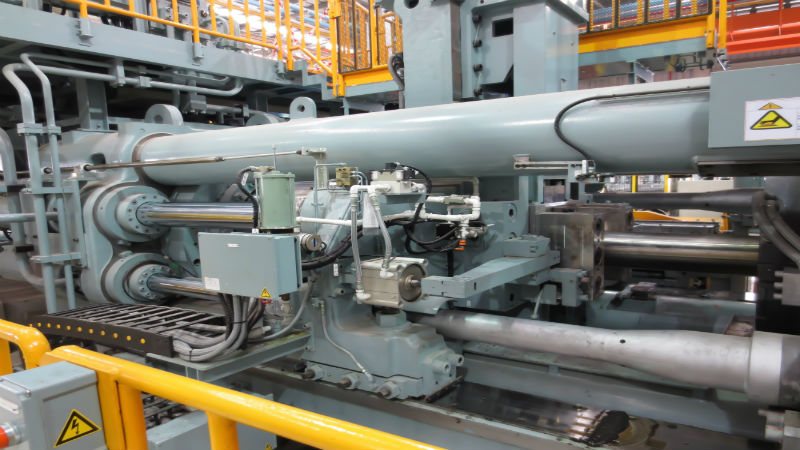

Precision parts are produced on dedicated mechanical devices. Contamination of these devices is highly probable and needs to be excluded because even the smallest, unseen metallic fines can easily damage the rotary couplings on expensive milling machines.

Manufacturers of coupling machinery require a filtration down as low as 5 microns. This is where your coolant filter proves its usefulness. As the surfaces of the tooling equipment become contaminated, by swarf and metallic fines, the precision parts may become less precise. The effectiveness of quick change tooling is boosted when coolant is cleaned through coolant filters.

Understanding Your Cutting Tools

Coolant is likely to contain abrasives and this will affect how tools become sensitive to those variations. Coolant must be clean to ensure the finish of the surface and the length of the life of the tools. The tools and parts may be damaged when abrasive fines are pumped into the working areas of the machinery.

Should you inspect a milling holder of almost any age, there will be a range of indentations which have been produced as chips are clamped between the spindle taper and the tool.

Failure to ensure that the coolant is filtered consistently may lead to poor accuracy of the tool being used and it may become out of balance.

It is not uncommon for small chips and harden swarf to seek a way through to the cutting edge, causing the coolant holes to become blocked. These chips will cause damage which is why regular inspection of the machinery and consistent filtering of the coolant is required.

Find the Experts in Your Industry

To save on your long-term expenses, especially maintenance on your tool cutting machinery, it is better to talk to experts within your industry who can supply the best equipment fitted with industry-leading coolant filters, to reduce wastage and regular replacement of precision parts.

By meeting with the experts and explaining your unique set of circumstances, they will assess your requirements and make professional decisions to help the long-term viability of your business.

There is every probability that those same experts will be able to help you with a variety of system machinery advantages, suitable for your industry.